SAP Production Planning at construction residents’ hands

Extending SAP Production Planning to the field right into the hands of construction leaders to avoid redundant work, material optimization, and production tracking.

Task

Extending SAP Production Planning to the field right into the hands of construction leaders to avoid redundant work, material optimization, and production tracking.

A successful business in the construction industry relies on optimizing supply and managing costs. This strategy requires a constant stream of relevant, accurate data flowing to decision-makers. Implementing SAP production planning is a significant investment to improve operations. How do we take this tech investment to the field where the actual work happens?

In the past, operations worked this way. Large companies with remote assets, such as factories, distribution hubs, and power stations, make huge efforts to avoid unexpected downtime that reduce supply chain performance. Maintenance supervisors prioritize orders and prepare preventive maintenance activities. Daily plan documents are published and sent to field specialists or service engineers who do the work. Paper documents are filled out on-site by people in the field. At the end of the day or when possible, the completed forms get returned to the administrative support staff. The staff then type the data into an application, such as mySAP Product Lifecycle Management (PLM).

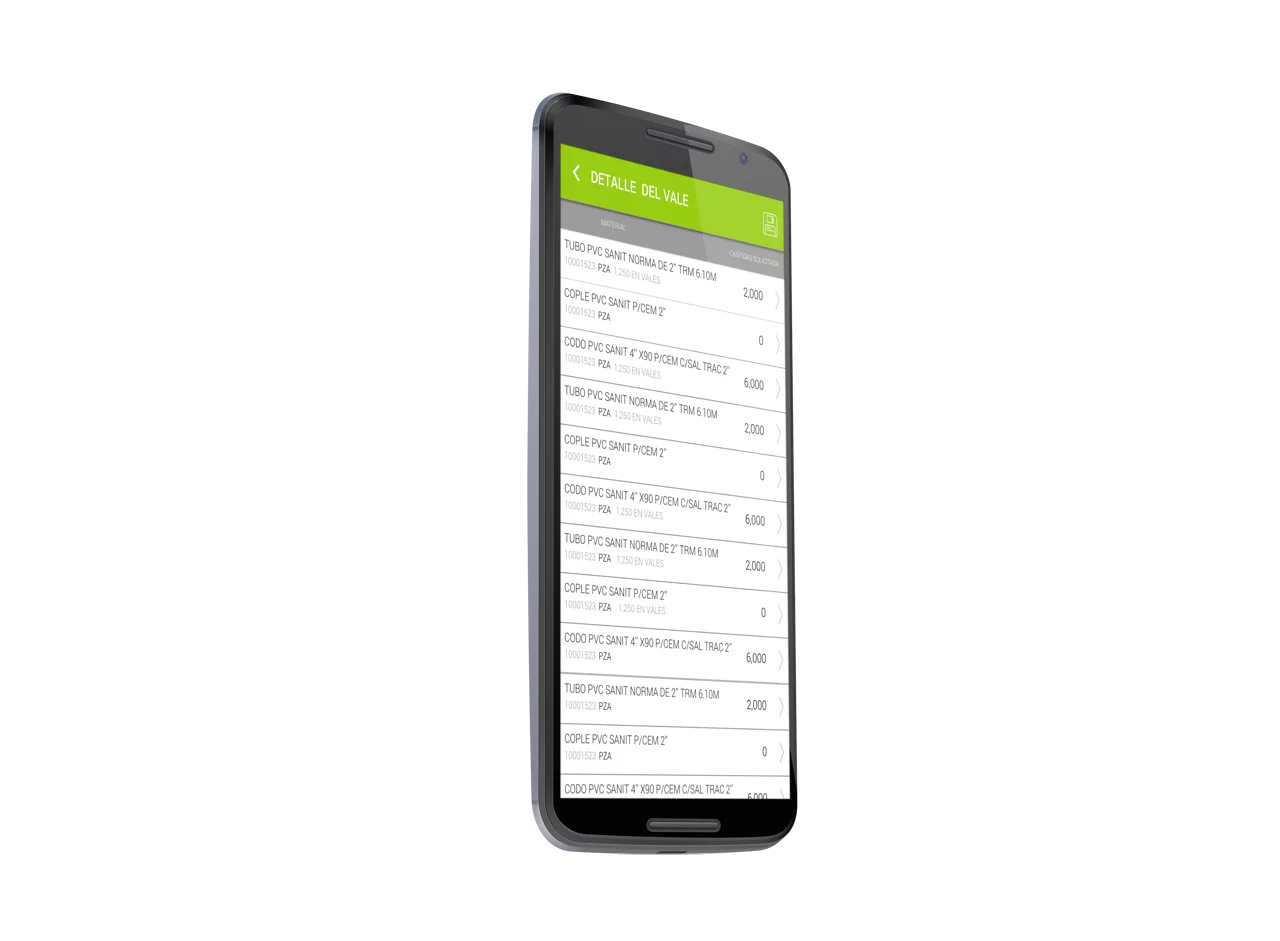

We implemented a ‘go mobile first‘ strategy that enables construction staff to manage material request tickets. Engineers can request assets directly from the field via their tablets. Thus, eliminating wasted time and travel costs. No more going back to the office to deliver office material to data entry workers. Now, management receives necessary data immediately, giving them the power to manage costs and operations better.

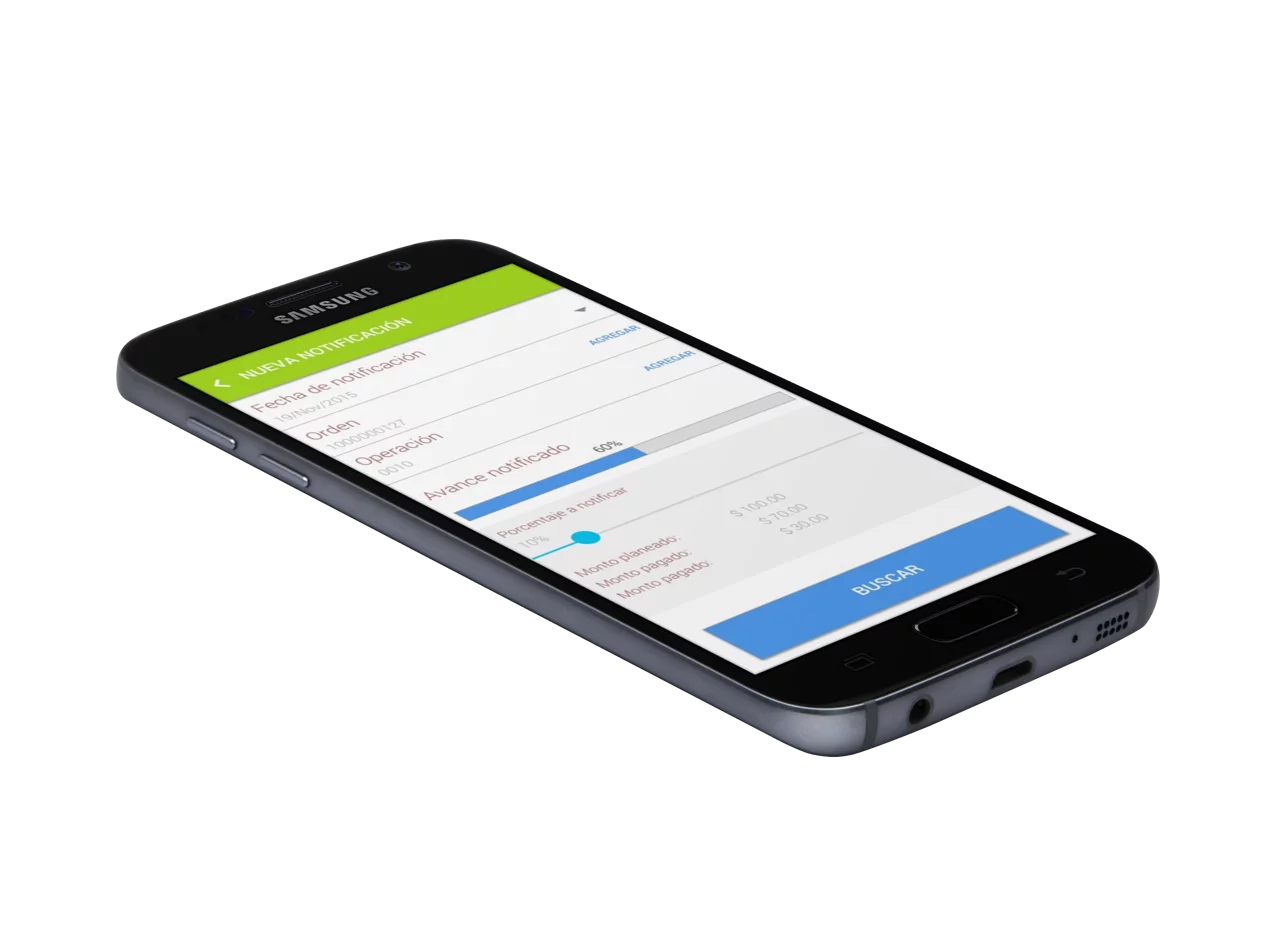

These devices are allowing resident engineers to notify work progress directly from the work zone in real-time.

Resident engineers can also perform quality control processes through the simple to use of electronic forms. They can specify the root cause of material failures at the job site. Very important to do this as it happens to report error trends accurately. This timely reporting method means process adjustments have a much better chance of making a positive impact sooner. This on-site digital capture is just another example of taking the planning process mobile.

We are looking forward to helping you make the first move today.